SES Training Solutions are pleased to offer a face fit testing solution for your business.

Our assessors have been trained to test the correct fitting of tight fitting RPE.

All our training and assessments are based on good industry practice, BSO ISO 16975-3:2017 and BS EN 149.

We also offer training to assist you in Respiratory Protective Devices – Selection, use and maintenance based up on good industry practice and PD ISO/TS 16975-1:2016.

We offer Qualitative (QLFT) Face Fit Testing and can complete this onsite or at our premises by appointment or group booking.

Qualitative fit testing (QLFT)

Qualitative fit testing (QLFT) uses an aerosol of either a bitter tasting substance (Bitrex) or a sweet substance (Saccharine) to challenge the face seal whilst the wearer undertakes 7 exercises (in a hood to contain the test substance). If after the 7 exercises (7 minutes), the candidate has not detected (tasted) the test substance, then that is regarded as a pass and a fit factor of 100 is assigned. (NB it is part of the protocol that at the end of the test, the candidate is required to break the seal to demonstrate how effective the seal has been).

Qualitative fit testing (QLFT) is a pass/fail test based on the wearer’s subjective assessment of any leakage through the face seal region by detecting the introduction of bitter- or sweet-tasting aerosol as a test agent.

QLFT methods are suitable for disposable and reusable half masks; they are not suitable for full-face masks. Although this type of test is based on subjective detection and response by the wearer of the RPE, it is important that it is administered by a fit tester competent in using this method.

Quantitative fit testing (QNFT)

Quantitative fit testing (QNFT) provides a numerical measure of how well a facepiece seals against a

wearer’s face; this is called a fit factor. These tests give an objective measure of face fit.

QNFT methods are suitable for disposable and reusable half masks and full face masks. Examples of

QNFT methods are:

ambient particle counting

controlled negative pressure (CNP)

Why is RPE Important?

RPE is important to everyone and if the user of respiratory protective equipment (RPE) is not trained in using their RPE correctly they may live to regret it. Unlike broken bones or cuts and bruises the damage from incorrect rpe or the incorrect use of the rpe is not immediately known and individuals may not show symptoms for sometime.

It is important to remember PPE and RPE are the last line of defence is considered to be at the bottom of the hierarchy of control measures and should only be used

after an acceptable case for its use has been established by way of an appropriate risk assessment.

RPDs – Respiratory Protective Devices are used to further reduce inhalation exposures to hazardous atmospheres:

— when sufficient engineering and administrative controls are lacking;

— when these controls are not reasonably practical (maintenance, escape or rescue work);

— prior to implementing or improving a control measure.

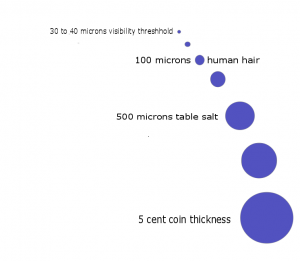

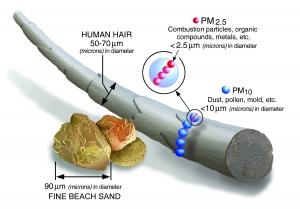

Dangerous airborne dust particles are defined in a size range between 2.5 and 10 microns.

PM2.5 (Less than 2.5 microns)

PM10 (less than 10 microns)

These respirable airborne size particles are able to enter and deposit within deep tissue parts of the lung over time causing lung disease. This is due to the human bodies own mechanisms not being able to capture or expel these invisible size particles.Asbestos fibres range between < 3 microns in diameter and > 5 microns in length (Airborne fibres).Coal dust particles range between 1 to 100 micronsCement dust particles range between 3 to 100 microns

What is PM, and how does it get into the air?

PM stands for particulate matter (also called particle pollution): the term for a mixture of solid particles and liquid droplets found in the air. Some particles, such as dust, dirt, soot, or smoke, are large or dark enough to be seen with the naked eye. Others are so small they can only be detected using an electron microscope.

Particle pollution includes:

- PM10 : inhalable particles, with diameters that are generally 10 micrometers and smaller; and

- PM2.5 : fine inhalable particles, with diameters that are generally 2.5 micrometers and smaller.

How small is 2.5 micrometers? Think about a single hair from your head. The average human hair is about 70 micrometers in diameter – making it 30 times larger than the largest fine particle.

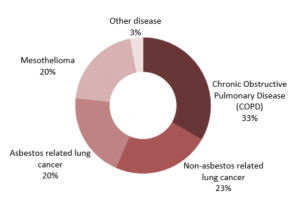

Lung disease contributing to estimated current annual deaths

A range of lung diseases can be caused by exposures in the workplace, including:

- Respiratory cancers, including lung cancer and mesothelioma

- Chronic Obstructive Pulmonary Disease (COPD)

- Silicosis, asbestosis and other forms of pneumoconiosis

- Occupational asthma

- Diffuse pleural thickening and pleural plaques

- Allergic alveolitis and byssinosis

Many of these are serious diseases which can often lead to death or substantial disability.

Most are “long latency” diseases, meaning they start to develop many years after the workplace exposures that caused them or contributed.

The main exceptions are occupational asthma and allergic alveolitis which can develop more quickly.

Current and recently occurring cases of long-latency diseases are mainly a reflection of past workplace conditions. However, many of the causative agents can still be present in workplaces and thus constitute a potential on-going hazard.

*Data as of HSE Statistics 2019

Legal Implications

Employers and businesses who do not utilise face fit testing of an individuals rpe that is provided to them will regret it later. If a business does not face fit test and record the information of the face fit results with a record of training then the business may find its insurance is limited or void.

Actionable by Inspectors

1)Poor suitability, use and maintenance aspects of RPE

2)No Face Fit Test

3)Fit Test Results are not readily available;

4)Wearer continuing to wear a mask which has been shown to not fit

5)Failure to produce results for more than one type of tight-fitting face piece worn in the workplace

If you would like to know more then please get in touch.

Our Face Fit team is made up of three Engineering Professionals with experience of using, selection and face fit testing of RPE. Our Engineers are supported with administration teams to ensure everything is run smoothly and efficiently.